Installed in PHEV and BEV electric vehicles to convert AC to DC for battery charging

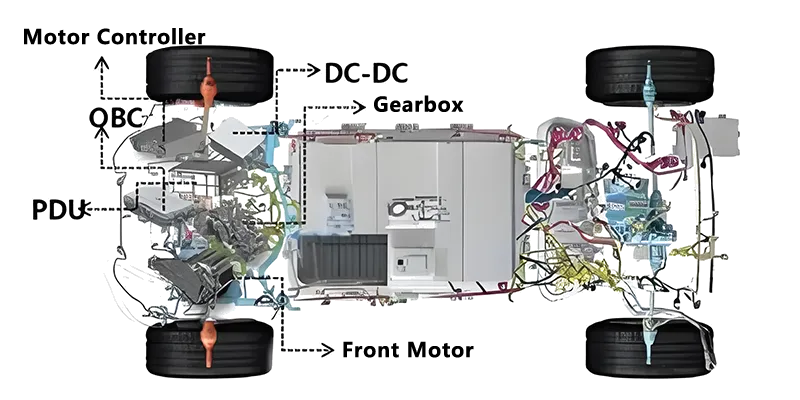

The on-board charger (OBC) is an internal system installed in plug-in hybrid (PHEV) and battery electric vehicles (BEV) to convert alternating current (AC) into direct current (DC) required for battery charging. It plays a crucial role in allowing EVs to charge their high-voltage batteries while parked, ensuring greater driving range through improved battery capacity and energy efficiency.

With battery voltage levels standardizing around 450V, and rising to higher voltages, OBCs help shorten charging times and minimize internal wiring. Whether using AC power at home or public/private charging stations, today's OBCs range from 1kW single-phase to 22kW three-phase converters. These chargers are designed to ensure high efficiency and fast charging, making them an essential component for maximizing vehicle range and performance.

| Model | HK-MF-48-40 | HK-MF-72-40 | HK-MF-108-32 | HK-MF-144-23 | HK-MF-312-10 |

| Cooling Method | Forced Air Cooling | Forced Air Cooling | Forced Air Cooling | Forced Air Cooling | Forced Air Cooling |

| Output Voltage | 48V | 72V | 108V | 144V | 312V |

| Output Voltage Range | 35-70V | 50-107V | 80-161V | 100-215V | 200-450V |

| Output Current | 40A | 40A | 32A | 23A | 10A |

| Output Power | 2000W@220VAC 1600W@110VAC | 3300W@220VAC 1650W@110VAC | 3300W@220VAC 1650W@110VAC | 3300W@220VAC 1650W@110VAC | 3300W@220VAC 1650W@110VAC |

| Power | 3.3kW | ||||

| Weight | 4.6kg | ||||

| Type | Model | Nominal Output Voltage | Output Voltage Range | Max. Output Current |

| 6.0kW Single-Phase On-Board Charger (Fan-Cooled) | RA6P0024 | 24V | 0-36VDC | 180A |

| RA6P0060 | 60V | 0-80VDC | 105A | |

| RA6P0080 | 80V | 0-105VDC | 75A | |

| RA6P0108 | 108V | 0-140VDC | 54A | |

| RA6P0144 | 144V | 0-180VDC | 39A | |

| RA6P0360 | 360V | 0-450VDC | 18A | |

| 6.0kW Three-Phase On-Board Charger (Fan-Cooled) | TR3610024 | 24V | 0-36VDC | 180A |

| TR3610060 | 60V | 0-80VDC | 105A | |

| TR3610080 | 80V | 0-105VDC | 75A | |

| TR3610108 | 108V | 0-140VDC | 54A | |

| TR3610144 | 144V | 0-180VDC | 39A | |

| TR3610360 | 360V | 0-450VDC | 18A |

| Type | Model | Nominal Output Voltage | Output Voltage Range | Max. Output Current |

| 6.6kW Low Voltage On-Board Charger (Fan-Cooled) | RA6P6072 | 72V | 0-95VDC | 90A |

| RA6P6048 | 48V | 0-68VDC | 120A | |

| RA6P6024 | 24V | 0-40VDC | 200A | |

| 6.6kW Middle/High Voltage On-Board Charger (Fan-Cooled) | RA6P6720 | 720V | 0-850VDC | 9A |

| RA6P6540 | 540V | 0-720VDC | 12A | |

| RA6P6360 | 360V | 0-500VDC | 18A | |

| RA6P6144 | 144V | 0-180VDC | 44A | |

| RA6P6108 | 108V | 0-135VDC | 60A | |

| RA6P6080 | 80V | 0-105VDC | 80A |

| Model | HK-LF-115-58 | HK-LF-144-46 | HK-LF-312-20 | HK-LF-540-12 |

| Cooling Method | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| Output Voltage | 115V | 144V | 312V | 540V |

| Output Voltage Range | 70-177V | 95-202V | 200-450V | 400-618V |

| Output Current | 58A | 46A | 20A | 14A |

| Output Power | 6000W@220VAC 3300W@110VAC | 6000W@220VAC 3300W@110VAC | 6000W@220VAC 3300W@110VAC | 6000W@220VAC 3300W@110VAC |

| Power | 6.6kW | |||

| Weight | 8.5kg | |||

| Model | HK-LW-312-20 | HK-LW-540-14 | HK-LW-600-12 |

| Nominal Output Voltage | 312V | 540V | 600V |

| Output Voltage Range | 200V-450V | 400V-680V | 400V-800V |

| Max. Output Current | 20A | 14A | 12A |

| Type | Model | Nominal Output Voltage | Output Voltage Range | Max. Output Current |

| 20.0kW Single Phase On-Board Charger (Water-Cooled) | RA22P0720 | 720V | 0-850VDC | 27A |

| RA22P0540 | 540V | 0-720VDC | 36A | |

| RA22P0360 | 360V | 0-500VDC | 54A | |

| RA22P0144 | 144V | 0-180VDC | 132A | |

| RA22P0108 | 108V | 0-135VDC | 180A | |

| RA22P0080 | 80V | 0-105VDC | 240A | |

| 20.0kW Three Phase On-Board Charger (Water-Cooled) | TR3636 | 720V | 0-850VDC | 27A |

| TR3635 | 540V | 0-720VDC | 36A | |

| TR3634 | 360V | 0-500VDC | 54A | |

| TR3633 | 144V | 0-180VDC | 132A | |

| TR3632 | 108V | 0-135VDC | 180A | |

| TR3631 | 80V | 0-105VDC | 240A |

The 3.3kW and 6.6kW OBC models offer excellent energy conversion efficiency, minimizing power loss during the charging process and ensuring a more sustainable energy transfer.

With a lightweight and compact structure, our on-board charger easily integrates into various vehicle architectures without compromising space or adding unnecessary weight.

Equipped with multiple safety protocols, including over-voltage, over-current, and temperature protection, the OBC ensures safe and reliable operation under all conditions.

Supporting smart charging protocols, our on-board charger is compatible with diverse grid standards, offering flexibility and convenience for users.

Designed to operate in a range of environmental conditions, our EV on-board charger withstands extreme temperatures, humidity, and vibrations, ensuring long-term durability.

Compliant with international standards and regulations, the 3.3kW and 6.6kW OBC models are built for the global market, making them suitable for various regions worldwide.

Our EV charging solutions are highly versatile, making them ideal for a range of applications, including passenger cars, commercial electric vehicles, yachts, electric motor engineering equipment, charging stations, and energy storage systems. Our on-board chargers are perfect for any setting that requires efficient voltage conversion. In particular, the 3.3kW on-board charger is the optimal solution for reliable and efficient charging on the go.

If you need help to identify the right solution, our expert will be happy to assist you. Please email us or give as a call.

The first step in our custom solution process is a comprehensive analysis of the client’s company and background. Our solutions team conducts a deep dive to understand the scale of the client’s business and their target customer base. We compile relevant information and create a potential supplier evaluation report, allowing us to effectively analyze and meet the client’s specific needs.

During the analysis of client’s requirements, our design team carefully examines the specifications required for the custom on-board charger (OBC), DC/DC converter, or integrated charging system. This includes verifying parameters such as product type, power capacity, size, integration level, interface types, cooling methods, and intended use.

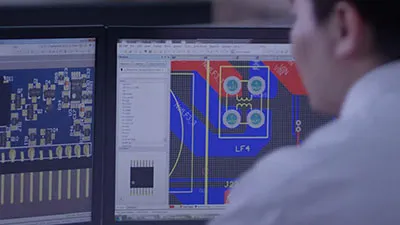

After all parameters have been verified and aligned with the needs analysis, our team proceeds with custom solution design. This phase focuses on improving or developing product molds and designing integrated PCB (Printed Circuit Board) layouts to meet the client's specific requirements in terms of integration and functionality.