TC Charger possesses a comprehensive R&D team, with expertise in areas such as product development, design, component selection, software platform development, EMC certification, and custom structural design. We own full intellectual property rights over our innovations. With advanced laboratories, we conduct extensive testing in electrical characteristics, reliability, safety regulations, and vehicle compatibility, ensuring the highest quality of our on-board chargers, DC/DC converters, and integrated charging systems.

Innovation is a core value at TC Charger, and we continuously strive to meet the industry's present and future demands for lightweight, high-density, and highly integrated EV charging and power supply devices. Our goal is to not only advance product technology but also to create value for customers, promote sustainable economic growth, and contribute to the long-term development of new energy vehicles industry.

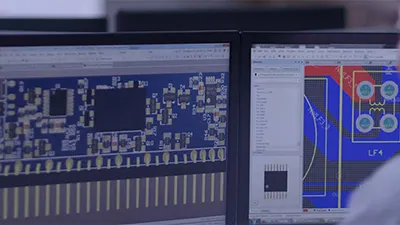

We are fully equipped with R&D experts in the new energy vehicle field, covering all aspects from component selection to EMC certification and structural design.

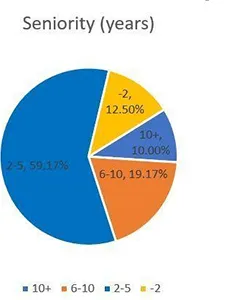

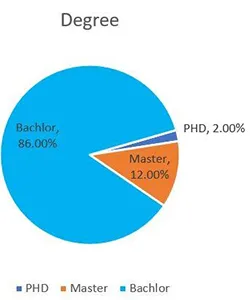

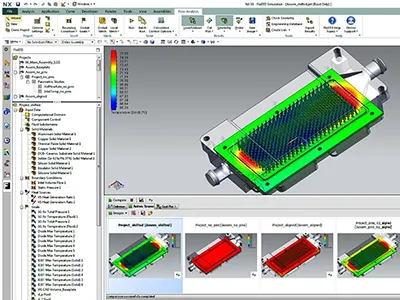

Our R&D team is composed of 110 highly skilled professionals, including 7 dedicated system maintenance personnel, 45 experts in hardware design, 10 specialists in structural design, and 12 software programmers. Supporting these efforts, TC Charger operates 13 fully equipped laboratories.

TC Charger possesses a comprehensive R&D team, with expertise in areas such as product development, design, component selection, software platform development, EMC certification, and custom structural design. We own full intellectual property rights over our innovations.

We operate four SMT production lines, covering an area of 1,520 square meters. The SMT workshop adheres to cleanliness level of ISO Class 8 (class 100K), ensuring high-quality production in a controlled environment.

TC Charger ensures strict quality control throughout the entire production cycle, conducting rigorous tests such as electrical performance tests, environmental reliability tests, and electromagnetic compatibility tests.

If you need help to identify the right solution, our expert will be happy to assist you. Please email us or give as a call.

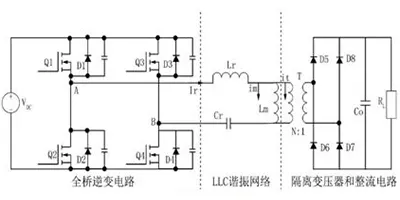

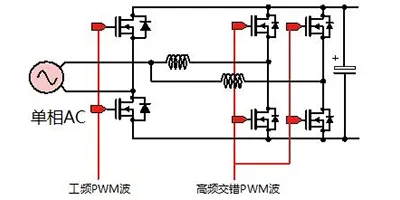

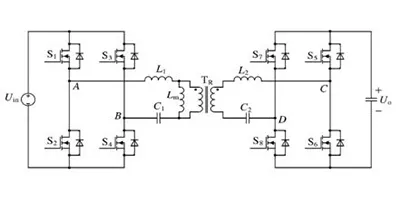

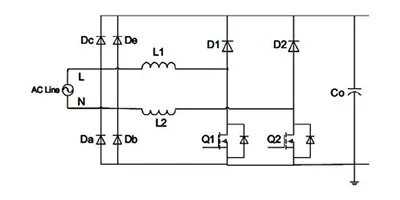

The on-board charger (OBC) is an internal system installed in plug-in hybrid (PHEV) and battery electric vehicles (BEV) to convert alternating current (AC) into direct current (DC) required for battery charging.

The DC-to-DC converter (DC/DC) is an essential component in new energy electric vehicles, responsible for converting high-voltage power from the main battery into low-voltage direct current used by the vehicle's electrical systems, including the auxiliary battery and other low-voltage loads.

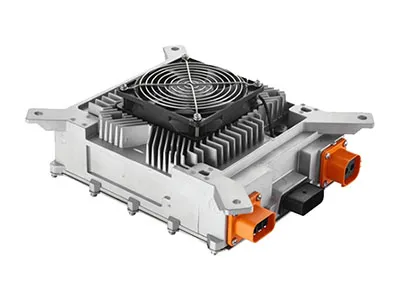

The 2-in-1 on-board charging system, also known as an integrated OBC (on-board charger) and DC-DC converter, is an electric vehicle charging solution that combines two essential functions: converting AC power to DC for efficient battery charging, while also stepping down high-voltage power to lower voltage levels for the vehicle’s electrical systems.

The 3-in-1 on-board charging system integrates an on-board charger (OBC), DC-DC converter, and a power distribution unit (PDU) into a single compact unit.

We take your onboard charging, DC/DC conversion, and high-voltage distribution systems from concept through project execution, testing, certification, and final mass production.

We ensure seamless production, adapting to changes in regulations and material availability.

We offer two categories of custom products based on the level of customization:

Original Design Manufacturing (ODM)

Original Equipment Manufacturing (OEM)