With the global new energy vehicle market developing at different rates across regions, TC Charger has the capability to customize on-board chargers to meet specific client needs. Each charger often requires adjustments to molds, interfaces, and other parameters before mass production can begin. As a trust-worthy and reliable supplier of smart automotive power solutions, TC Charger excels in offering tailored designs and production capabilities to meet unique demands for chargers, converters, and integrated products.

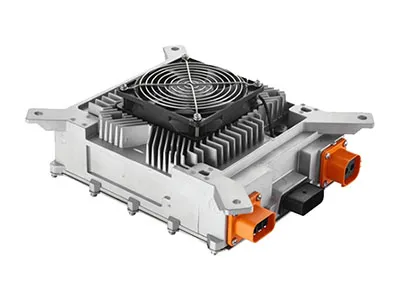

Our integrated 2-in-1 (OBC + DC/DC) and 3-in-1 (OBC + DC/DC + PDU) charging system streamline vehicle wiring, reducing the number of connectors and optimizing high and low-voltage harnesses. This results in more efficient space usage and a compact design.

Our custom solutions are built to meet the unique specifications of each client. Here's how we work:

We take your onboard charging, DC/DC conversion, and high-voltage distribution systems from concept through project execution, testing, certification, and final mass production.

We ensure seamless production, adapting to changes in regulations and material availability.

We offer two categories of custom products based on the level of customization:

Innovation and platform development are at the core of our entire product range, including our OEM/ODM custom integrated on-board charger solutions.

The benefits of using our platform-based development approach include:

Our design platform for custom products, such as integrated on-board chargers or DC/DC converters, is highly modular and reusable, developed through innovative processes that include high-frequency power conversion solutions. This allows us to adapt existing technologies to new products without the need to start from scratch for every project. Our platform-based approach enables quick customization in areas like component selection, software development, and structural design, supporting both analog and digital control. Moreover, it ensures that our integrated on-board chargers meet stringent industry standards such as EMC certification. For demanding applications that require high peak power and advanced functionality, our platforms ensure reliable operation by effectively managing power outputs, with built-in protections against overload scenarios.

We customize the OBC for optimal output power and meet increasing market demands for high current, low loss, heat resistance, and compact design. We customize key configuration parameters such as input/output voltage measurements, noise reduction, electromagnetic compatibility (EMC), full-wave rectifier circuits, and voltage conversion circuits. Our 3.3kW and 6.6kW OBCs meet the essential charging needs of modern EVs. With over 500 test and quality control devices in our production workshop, we guarantee high production standards at every step of manufacturing process.

Our DC/DC solutions are designed for products requiring high-efficiency power conversion and provide high power density with efficient output. Our power platform offers both isolated and non-isolated power conversion solutions, ranging from 300W to 6000W. For input voltages below 60V, non-isolated platforms offer lower costs, higher efficiency, and greater output power, while isolated systems are used for input voltages above 60V to provide safer protection. Both systems ensure the highest efficiency and, when combined with integrated filters and input protection, enable the development of compact, custom DC/DC converters.

Our solutions meet industry standards such as GB/T 40432-2021 and BT/SGMWJ 0863-2022, ensuring compliance with the latest technical requirements and testing methods for electric vehicle charging systems. In addition, we conduct Potential Failure Mode and Effects Analysis (FMEA) to identify and address potential issues at every production stage, minimizing risks and ensuring smooth delivery from prototype development to mass production.

The first step in our custom solution process is a comprehensive analysis of the client’s company and background. Our solutions team conducts a deep dive to understand the scale of the client’s business and their target customer base. We compile relevant information and create a potential supplier evaluation report, allowing us to effectively analyze and meet the client’s specific needs.

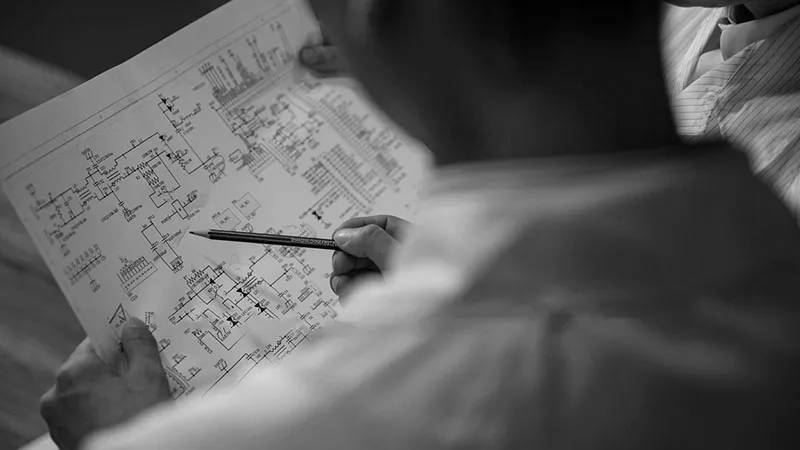

During the analysis of client’s requirements, our design team carefully examines the specifications required for the custom on-board charger (OBC), DC/DC converter, or integrated charging system. This includes verifying parameters such as product type, power capacity, size, integration level, interface types, cooling methods, and intended use. We also assess the client’s long-term objectives to ensure the product meets performance expectations in real-world applications. Once all parameters are finalized, the detailed specifications are provided to the client for final confirmation.

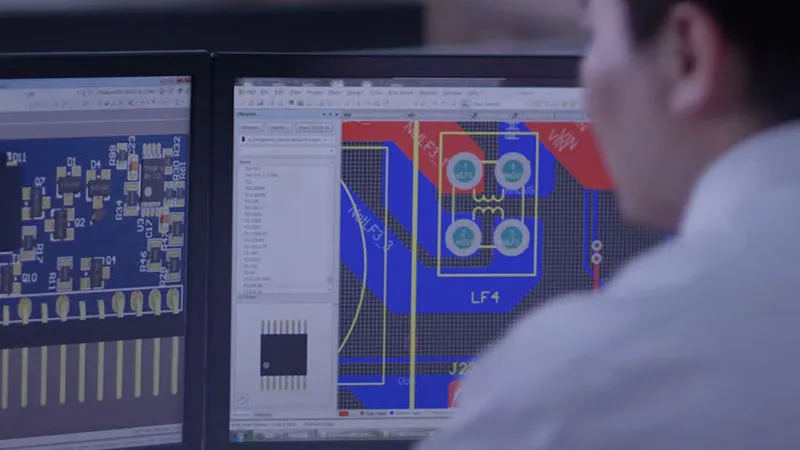

After all parameters have been verified and aligned with the needs analysis, our team proceeds with custom solution design. This phase focuses on improving or developing product molds and designing integrated PCB (Printed Circuit Board) layouts to meet the client's specific requirements in terms of integration and functionality. We also create a detailed project schedule and oversee the entire lifecycle of the project, conducting periodic reviews to track progress and report updates at each phase.

After the solution is finalized, our R&D team begins the development of custom applications and the creation of 3D digital models. These models undergo computer-simulated animations to test the product's feasibility and stability, while optimizing the structural design, heat dissipation, and airflow resistance. This simulation process allows us to identify potential issues and develop solutions before moving into production. Once all tests are completed successfully, the project advances to the sample production phase.

Based on the initial design parameters and solution, we develop a prototype that meets the client’s functional requirements. This prototype undergoes multiple quality inspections for quality control and tests to ensure it performs as expected. After the sample is delivered to the client for installation and real-world use, we gather feedback on any issues encountered during operation. This feedback is then analyzed, leading to adjustments in parameters, structural optimization, and improvements to the internal design.

Once all adjustments are finalized, mass production begins. TC Charger is equipped with fully automated production and testing facilities, with a monthly production capacity of up to 40,000 units. We meet large-scale customization demands while maintaining strict quality control at every stage of production. Each EV on-board charger and power supply device is manufactured to comply with international certification standards, ensuring that we deliver high-quality products on time and in line with client specifications.

If you need help to identify the right solution, our expert will be happy to assist you. Please email us or give as a call.

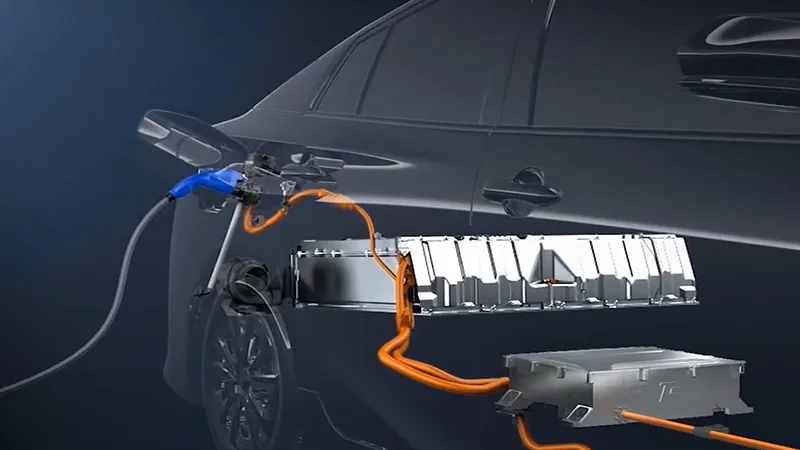

The on-board charger (OBC) is an internal system installed in plug-in hybrid (PHEV) and battery electric vehicles (BEV) to convert alternating current (AC) into direct current (DC) required for battery charging.

The DC-to-DC converter (DC/DC) is an essential component in new energy electric vehicles, responsible for converting high-voltage power from the main battery into low-voltage direct current used by the vehicle's electrical systems, including the auxiliary battery and other low-voltage loads.

The 2-in-1 on-board charging system, also known as an integrated OBC (on-board charger) and DC-DC converter, is an electric vehicle charging solution that combines two essential functions: converting AC power to DC for efficient battery charging, while also stepping down high-voltage power to lower voltage levels for the vehicle’s electrical systems.

The 3-in-1 on-board charging system integrates an on-board charger (OBC), DC-DC converter, and a power distribution unit (PDU) into a single compact unit.