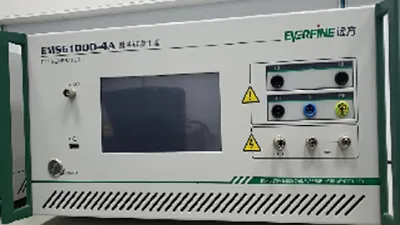

TC Charger ensures strict quality control throughout the entire production cycle, conducting rigorous tests such as electrical performance tests, environmental reliability tests, and electromagnetic compatibility tests. Our key testing equipment includes Chroma 8000 electrical performance testing systems, air-tightness leak detectors, high-low temperature and humidity test chambers, salt spray test chambers, electrical safety analyzers, AC/DC power sources, EMI receivers, EMI antennas, surge generators, electrostatic discharge guns, and more.

All testing is carried out using in-house equipment, which is included in a comprehensive calibration plan. We have obtained various quality certifications, including IATF16949:2016, ISO14001 for environmental management, and OHSAS18001 for health and safety, as well as MES and PLM system certifications.

Our component warehouse maintains sealed, temperature and humidity-controlled conditions to ensure optimal storage. The assembly workshop operates in a class 500K cleanroom, while the SMT workshop adheres to class 100K cleanroom standards. To further enhance safety and precision, we have implemented advanced electrostatic protection systems, including air shower doors, static discharge systems, and anti-static flooring. Our hardware warehouse utilizes an automated vertical storage system, ensuring efficient, unmanned storage management.

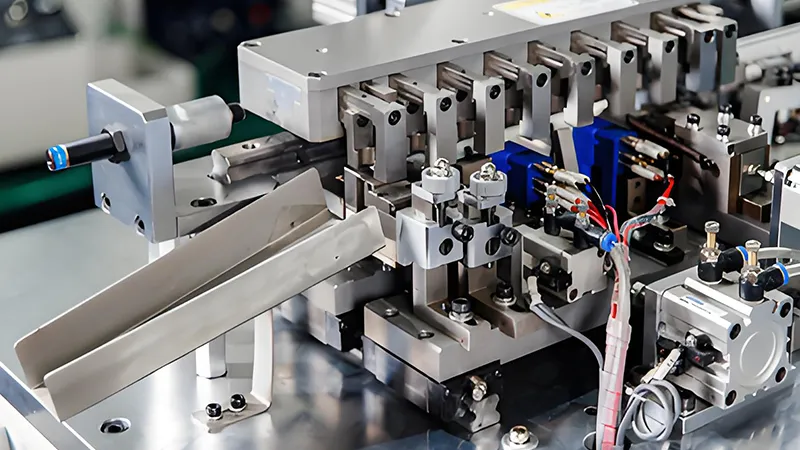

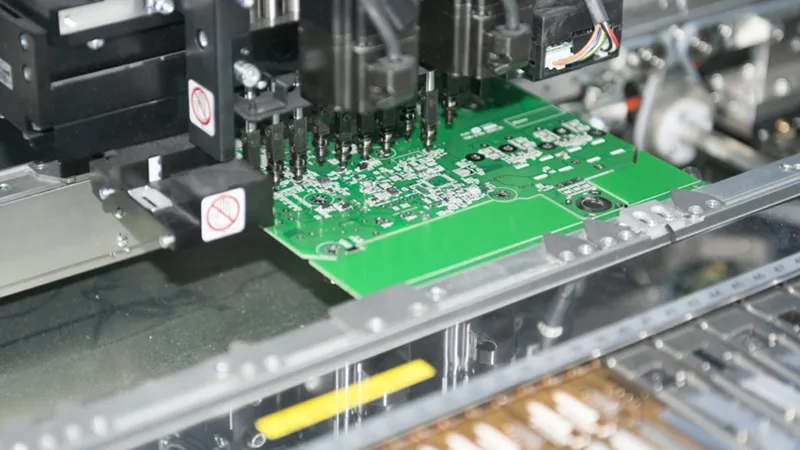

Our SMT workshop is equipped with four fully automated YAMAHA SMT lines. The testing process includes advanced equipment such as automatic optical inspection systems, solder paste inspection systems, Chroma programmable test systems, and ICT in-line testers. We also employ a fully automated closed-loop aging chamber with 11 testing checkpoints. In the assembly workshop, automation is taken further with the use of robotic welding systems, automatic screw-tightening robots, laser engraving equipment, and a fully automated assembly line integrated with the MES (Manufacturing Execution System).

We use internationally recognized, automotive-grade electronic components from well-renowned global brands, ensuring that all parts meet the IP67 waterproof testing standards and fully comply with national regulations. We strive to continue with our innovation with the application of new materials and are recognized as one of the well-established suppliers in China using silicon carbide materials for new energy vehicles. We have implemented the IATF16949 quality system across the entire supply chain, with strict quality control measures applied to all four workshops and 15 manufacturing processes, overseen by 10 quality control checkpoints to ensure quality is maintained from the source.

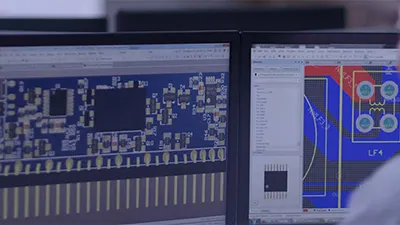

TC Charger possesses a comprehensive R&D team, with expertise in areas such as product development, design, component selection, software platform development, EMC certification, and custom structural design. We own full intellectual property rights over our innovations.

We operate four SMT production lines, covering an area of 1,520 square meters. The SMT workshop adheres to cleanliness level of ISO Class 8 (class 100K), ensuring high-quality production in a controlled environment.

TC Charger ensures strict quality control throughout the entire production cycle, conducting rigorous tests such as electrical performance tests, environmental reliability tests, and electromagnetic compatibility tests.

If you need help to identify the right solution, our expert will be happy to assist you. Please email us or give as a call.

The on-board charger (OBC) is an internal system installed in plug-in hybrid (PHEV) and battery electric vehicles (BEV) to convert alternating current (AC) into direct current (DC) required for battery charging.

The DC-to-DC converter (DC/DC) is an essential component in new energy electric vehicles, responsible for converting high-voltage power from the main battery into low-voltage direct current used by the vehicle's electrical systems, including the auxiliary battery and other low-voltage loads.

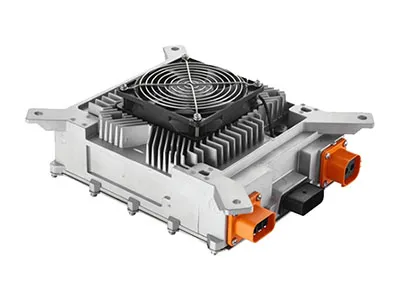

The 2-in-1 on-board charging system, also known as an integrated OBC (on-board charger) and DC-DC converter, is an electric vehicle charging solution that combines two essential functions: converting AC power to DC for efficient battery charging, while also stepping down high-voltage power to lower voltage levels for the vehicle’s electrical systems.

The 3-in-1 on-board charging system integrates an on-board charger (OBC), DC-DC converter, and a power distribution unit (PDU) into a single compact unit.

We take your onboard charging, DC/DC conversion, and high-voltage distribution systems from concept through project execution, testing, certification, and final mass production.

We ensure seamless production, adapting to changes in regulations and material availability.

We offer two categories of custom products based on the level of customization:

Original Design Manufacturing (ODM)

Original Equipment Manufacturing (OEM)